Written by the PA Consulting team

With the coronavirus pandemic escalating and the country fast running out of life-saving ventilators, the UK Government asked PA to lead one of the largest mobilisations of innovation, science and engineering since the Second World War.

Against all odds, the UK Ventilator Challenge made sure that everyone in the UK who needed a ventilator got one. Here, we share how we brought an agile and diverse team from across the public and private sectors together to achieve one of the most mission-critical challenges of recent times. This life-changing programme offers insights for any leader seeking to drive breakthrough innovation, at pace, in complex and challenging circumstances.

In early March government modelling predicted that the UK’s National Health Service (NHS), already straining under the immense challenges of responding to the coronavirus pandemic, would run out of ventilators in a matter of weeks. For many hospitalised patients, access to this critical and complex piece of medical equipment would mean the difference between life and death. Now, the government was asking us to lead an emergency response to manufacture and distribute ventilators at unprecedented pace and scale.

The goal was monumental: produce 30,000 ventilators in just eight weeks to save patients’ lives all over the country. To do this, we’d need to draw up requirements and specifications for new designs, and engage manufacturers of existing ventilator devices, along with a host of industry partners – like Ford, Rolls Royce and aerospace company Meggitt – with no experience creating ventilators but whose manufacturing, logistics and design expertise would be vital. We’d need to source millions of parts from across the globe, and bring shuttered factories back online during the greatest period of global supply chain disruption seen in our lifetimes. We’d need to put the ventilators through clinical trials, and get them approved by the regulator and distributed to hospitals across the country where demand levels changed by the hour. And we’d need to train thousands of medical professionals on their use.

Our sense of purpose, our trusting relationship with government built over decades of delivering outstanding work for the public sector, our ability to offer a wide breadth of expert skills, and the respect we had for, and inspired amongst, all the partners were just some of the reasons for the success of this incredibly complex project.

Key Successes

Scaled up enough existing, and designed enough new, ventilators that every patient who needed a ventilator had one.

Responded to, triaged and catalogued more than 5,000 offers of help, creating a database of 5,400 materials and component suppliers.

Enabled medical devices manufacturer Penlon to make more ventilators in one day than it used to make in ten months.

Coordinated the shipment of over 40 million ventilator parts from 21 countries within three weeks.

Receiving the call

Our Chief Innovation Officer, Frazer Bennett, remembers the moment his colleague phoned to explain the job at hand. “I said to him that most of what you’ve just described is completely impossible,” recalls Frazer, “because, first, you can’t design a medical device and bring it to manufacture in eight weeks. It takes two years to design something like this. And second, you can’t ramp up the production of complex existing devices in only two months, because the supply chain won’t cope.” His colleague didn’t miss a beat, responding: “I know that, but we must do it in eight weeks. Lives depend on it”.

With PA in the lead role, on 16 March, Prime Minister Boris Johnson announced the VentilatorChallengeUK in what the media dubbed “a call to arms.” The Government asked companies from across the UK to design a ventilator that could meet regulatory approval and be manufactured at scale within the eight-week timeline. Companies that already produced ventilators were asked to scale their manufacturing capacity.

Setting out the strategy

We got to work immediately. Within 48 hours of the announcement, we started to deliver on our detailed plan for how to get new ventilators designed, approved for manufacture through clinical trials and into mass manufacture – and to ramp up production of existing ventilators. Our medical device designers, logistics and clinical experts, and those capable of managing complex programmes were all focused on a common objective.

We set out the initial requirements for the emergency ventilator device. After all, participating organisations needed to know what they were building to. Throughout the crisis, we continued to refine these requirements in response to the evolving scientific and clinical understanding of COVID-19. We worked closely, every day, with clinicians and the regulator, the Medicines and Healthcare Products Regulatory Agency (MHRA).

In parallel, our team got busy triaging offers to help. Within days, hundreds of offers – from large multinational corporations to small medical device businesses and individuals – flooded in; a number that would eventually grow to over 5,000 in just a few weeks. Our experts investigated each request, verifying its authenticity, quickly deciding on technical relevance, prioritising and following up.

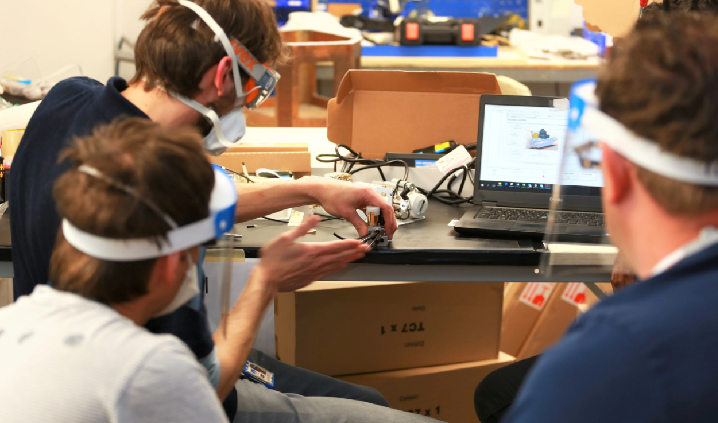

There were more than 200 ventilator designs to assess. In most cases, these weren’t just drawings; they were working prototypes. The best way to understand which of the models would be effective, durable and scalable was to get to the core: dismantle, look at and feel every piece. Our deep technical understanding of how you build medical devices – our clinical experts and designers have been at it for decades – proved critical. “Our experts quickly found out what worked and what didn’t,” explains Frazer. “We needed to balance technical capability, manufacturing feasibility and, most importantly, clinical utility.”

The goal was always to narrow the 200 down to a handful of designs that showed the most promise. Big decisions had to be made quickly.

Coordinating multiple, complex dimensions

Each hour brought a new challenge for the team. “Our biggest enemy was time. It was time that was going to derail us. And the thing that was going to eat up time the most was the decision-making process,” says Simon Collier, PA healthcare expert.

So, we created a Technical Design Authority (TDA), which served as the primary body for making recommendations about the choice of ventilator designs. Although different for every initiative, we’ve refined this TDA-model through years of delivering major programmes as varied as nuclear submarine development to the redesign of public services. We staffed the TDA with PA people with deep expertise in healthcare, medical device development, data modelling, product design and engineering, and public sector procurement and supply chain design. We also brought in the most experienced clinical experts from across the UK, along with government representatives and the MHRA.

The TDA gave us the ability to get the right decisions made by the right people at the right time. “In a matter of hours, we were able to translate incredibly complex technical information coming in from dozens of places into a format that enabled clinicians to make recommendations, and senior government officials to quickly absorb and make decisions,” explains Simon, who oversaw the TDA’s work. “We secured their approval, received updated instructions, then translated it all back to industry. These were literally life-changing decisions. That happened every single day.”

Each evening, a call took place with Lord Agnew, Minister of State at the Cabinet Office, to brief the Cabinet Office Minister Michael Gove and the Prime Minister’s team. “We knew what it took to inspire a decision to get made and we knew how to build trusting relationships,” says Barbara Bradley, PA public services expert, who has built her career working at senior levels of government. “All egos were left at the door. Everyone took their badges off. It was about the blended team we had between the regulator, Cabinet Office, the Department of Health and us. Everyone was mission focused. That was absolutely critical to the success of what we achieved.”

Within around four weeks of the initial call to arms, the TDA narrowed the 200 designs down to fifteen, based on the clinical effectiveness of each ventilator design. At this point, our team had been operating non-stop: seven days a week, eighteen hours a day. “We knew we couldn’t stop, we couldn’t take our foot off the pedal, there was just too much at stake,” recalls Simon. “Critical at this point was work inside the team on building resilience, supporting each other, and creating the right environment for everyone to be their very best. It really worked. Something I’ll take with me forever.”

Managing 15 competing workstreams

It would take 40 million components, sourced from 21 countries, to complete the ventilators on time. Our team knew this would require speed and scale the likes of which the UK industry had never seen before.

We set up a manufacturing programme for each of the fifteen designs. This meant building relationships between our network into the Cambridge innovation cluster, a group of innovation-focused companies located in and around Cambridge in the UK. We also brought together medical device designers, parts suppliers and some of the best large-scale manufacturers in the UK and Europe, including McLaren, Airbus and Siemens.

Our supply chain and sourcing experts built a supply chain and sourcing strategy from scratch. “We had to look at thousands of different components across the different devices, figure out where we could get them and where there might be an international shortage,” says Frazer. Global competition for parts was fierce: the UK was far from the only country desperately trying to source parts for the devices and get hold of the consumables that go with them. And the design requirements evolved frequently throughout the project. “It was a moving target every day,” says Frazer. To top it all off, the fifteen workstreams were often competing for the same parts. We were right in the middle, ensuring everyone could find what they needed.

We created commercial agreements on behalf of the government with thousands of manufacturers from around the globe, even arranging to reopen a factory in Mexico that had been mothballed to source specialist components. Throughout, our commercial team in the Cabinet Office ensured everything was done to the highest commercial standards. “You feel this tremendous responsibility when you’re spending the public purse to get it right every time,” says Barbara. “There’s no margin for error.”

Our efforts and energies ranged from the most complex through to reacting to simple points of failure to keep the programme on track. For example, we brokered commercial partnerships on behalf of government with transportation companies. Yet all too often, taking the traditional route wasn’t going to be fast enough. So, we got inventive. To get thousands of batteries out of China, during a public holiday, we arranged a fleet of small vans to move them across the border to Hong Kong. One of our team even drove from London to Wales and back – five hours each way – to get a single part for a single ventilator.

All medical devices, and their manufacturing process, must undergo stringent evaluation and regulatory approval. We ensured independent testing organisation MD-TEC could do the rapid testing needed to support this regulatory approval.

As the clock ticked, it became clear that three new designs – plus an existing model whose production could scale – offered the best chance of achieving the objectives. We focused all our efforts on them.

Delivering to the right place at the right time

Four weeks from the Prime Minister’s announcement, the first ventilators began rolling off the assembly line. Penlon, the manufacturer of the first ventilator produced as part of the challenge, would go on to scale from producing 150 ventilators a year to 400 every single day.

We were increasingly confident we could manufacture the number of ventilators required, but could we get them into the hands of the NHS staff who desperately needed them?

At that point, our supply chain experts switched gears – it was all about distribution and getting the right number of ventilators to the right places. It would usually take six months to a year to set up the kind of distribution system needed. We had days.

NHS Operations had to make critical decisions around how many ventilators should go where – a major challenge as the disease progressed. The fast-moving nature of the pandemic, and changing expectations, meant we needed to keep one step ahead of hospital needs. Our health, supply chain and product engineering experts worked in agile teams and around the clock. They collaborated with the Ministry of Defence’s trading entity, the Department for Health and Social Care, the NHS, and the Cabinet Office to make sure the ventilators ended up in the right places.

These were new machines, which meant they needed detailed instructions for use. And medical professionals had to be trained on their use. A small team of our health, training and transformation experts, as well as graphic designers, joined forces with the country’s leading clinicians, NHS e-learning specialists, MD-TEC representatives and the various manufacturers to develop manuals and training resources like videos, written guides and a support helpline. We worked at the point of care with the frontline staff to help everyone understand how to use the machines.

Reflecting on the success of UK industry

Just 15 weeks from the Prime Minister’s announcement, we’d delivered more than 13,000 ventilators through the Ventilator Challenge. Every single patient who needed a ventilator had one.

The number of people admitted to hospital requiring ventilation had been declining for some weeks. We’d got over the peak. The actions taken by government, most consequential of all, the decision to put the country in ‘lockdown’, had flattened the curve. Previous models calling for 30,000 ventilators had been revised downward in the weeks prior.

And so, as demand continued to dampen, we shifted focus to drawing the effort to a close.

Far from simply turning off the lights, the winddown efforts proved complex. For instance, we put in place systems for the upkeep of ventilators that had been produced. We also wanted to ensure funds that had been spent procuring parts for unused equipment wouldn’t be lost. So, we negotiated buybacks from suppliers and found buyers in other industries, using appropriate government frameworks. In other instances, we found use for the parts in the Department of Health’s existing procurement system. We were methodical in documenting our processes so there was a clear roadmap should the government need to suddenly ramp up production in response to a rise in new cases of COVID-19.

Four months to the day from the Prime Minister’s initial call to arms, Frazer, Barbara and Simon gathered on a videoconference (the UK remained in partial lockdown) to reflect on what the project achieved.

Barbara says there were several factors that made the work a success: “There was our trusting relationship with government built over decades of delivering outstanding work. There was the team’s attitude – they had this huge sense of purpose. No matter the ask, whether from government or industry, the response was ‘yes, we’ll find a way to get it done.’”

Barbara also points to the ability to quickly gather experts from across PA who had all the skills needed: “It was like speaking multiple languages – technical, medical, design, manufacture distribution, regulation. We had the best possible people working on exactly the right tasks. And we could translate that information for senior government figures, which helped them make decisions quickly at an incredibly difficult time.”

“We also had some lighter moments, which kept us going,” reminds Simon. “I mean, it was incredibly stressful at times, and the mission couldn’t have been more serious. There were nearly 8,000 people involved at one point or another. And everything had to have happened yesterday. But as a team, we as PA and our partners genuinely enjoyed working with one another. We trusted and respected each other. That was key. I am full of ideas about how I will take that into my next project, and the next after that. I’ve learned so much.”

The ultimate impact of the Ventilator Challenge cannot be understated, says Frazer: “In a matter of weeks after we started, lives were being saved using ventilators that were designed and manufactured in this programme. That’s three years’ work right there that we did in weeks. We saved lives by achieving the impossible. What’s not to like?”

This blog was originally posted on PA Consulting's website here.